Our Products

Ultrasonic Packaging

Advantages

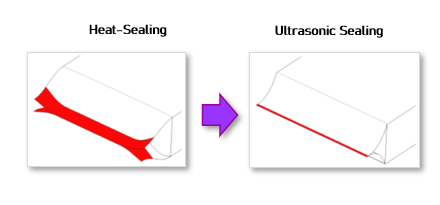

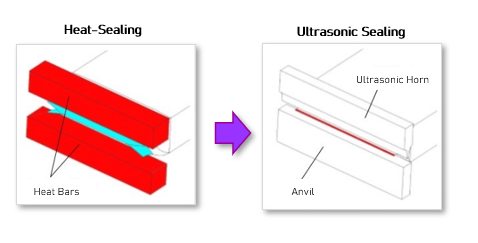

Ultrasonic sealing is more environmentally friendly, reducing both material and energy consumption when compared to heat-sealing.

Reducing Material Consumption

- Heat-sealing requires a 10-15mm wide seam for an airtight seal. Ultrasonic sealing can achieve the same result with only a 1mm wide line, drastically reducing the amount of consumed plastic.

Quality Sealed Surface

- With traditional heat-sealing, making the seal faster requires the heat-bar to run at a higher temp. However, this can effect certain materials differently and often creates wrinkles on the package. Ultrasonic sealing requires so little surface area that it can consistently provide wrinkle-free results.

- Unlike heat-sealing, ultrasonic can seal bags that use laminated materials.

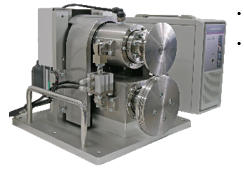

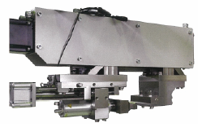

Rotary Ultrasonic Sealing Unit

- A Rotating Disk horn allows for fast, continuous sealing

- Compact all-in-one set includes the ultrasonic welder, horn and anvil, making it easy to change out your existing heat seal unit

Wide Sealing by Multi-Transducer Horn

- Joints of up to 300mm are possible

- A single 1mm wide joint yields the same strong, hermetic seal as a wider or multi-seam heat sealer

Sealed Joints are made without Direct Heat

- Ultrasonic seals do not radiate heat that may damage the packaged contents

- Heat-sealers depend on heated bars that run consistently at high temperatures, requiring a constant supply of power. Ultrasonic sealing works without pre-heating and completes the seal in less time with lower energy

- Reduces burnt material compared to heat-sealing bars

.

Bag Top Sealing Unit

- Ultrasonic joints make a complete seal even if the bag filling is between the two sheets of welded material

- Compact, all-in-one set includes the ultrasonic welder, horn, and anvil, making it easy to change out your existing heat sealing. unit

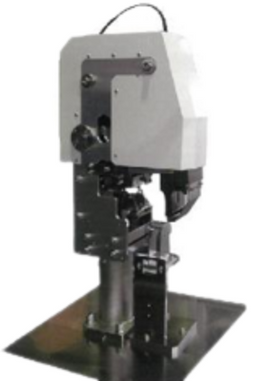

Vertical Tube Sealing Unit

•Much smaller footprint compared with horizontal ultrasonic sealing unit and possible to mount on rotary packaging automation.

•Ultrasonic joints make a complete seal even if the filling is between the two welded sheets.

•Compact all-in-one (including ultrasonic welder, horn and anvil) unit makes it easy to replacement of the existing heat seal unit

FAQs

Plastic Welding Technology

-

What payment methods do you accept?

When purchasing our plastic welding technology we accept all major credit and debit cards including but not limited to Amex, Express, Visa, and Mastercard. Additionally, other businesses can pay for our plastic welding technology.

-

What if my product gets damaged?

We apologize if any of our plastic welding technology arrives damaged or becomes damaged. Please contact us as soon as possible about your damaged plastic welding technology.

-

Privacy Policy

Our plastic welding technology site does not sell your information to any third parties. Our website is 100% secure and we only ask for your contact information, such as phone number and email, so that we can contact you about your order, or if you have any questions. We do not sell this information. We do not require any other additional information such as social security numbers.

-

Terms of Service

All images and information on this website are either property of Sedeco USA, Inc. or licensed. When visiting our plastic welding technology site all customers are agreeing to appropriately use all content and follow all copyright laws.

Ready to Step Into the Cutting Edge?

Contact Us

Headquarters

6236B Centre Park Drive

West Chester Twp

OH 45069