Our Products

Components for Automation

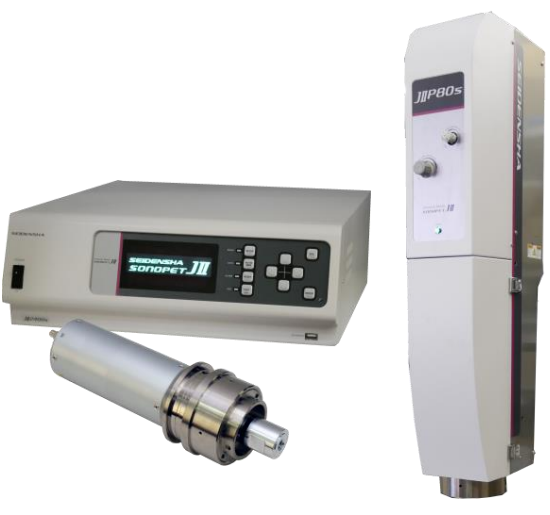

Seidensha’s SONOPET Ultrasonic Welders are designed to be easily integrated into automated systems. Whether separated component by component or used with our JII Bench Press Head, we have everything you need to make fully-automated, turnkey systems that deliver high quality, repeatable results.

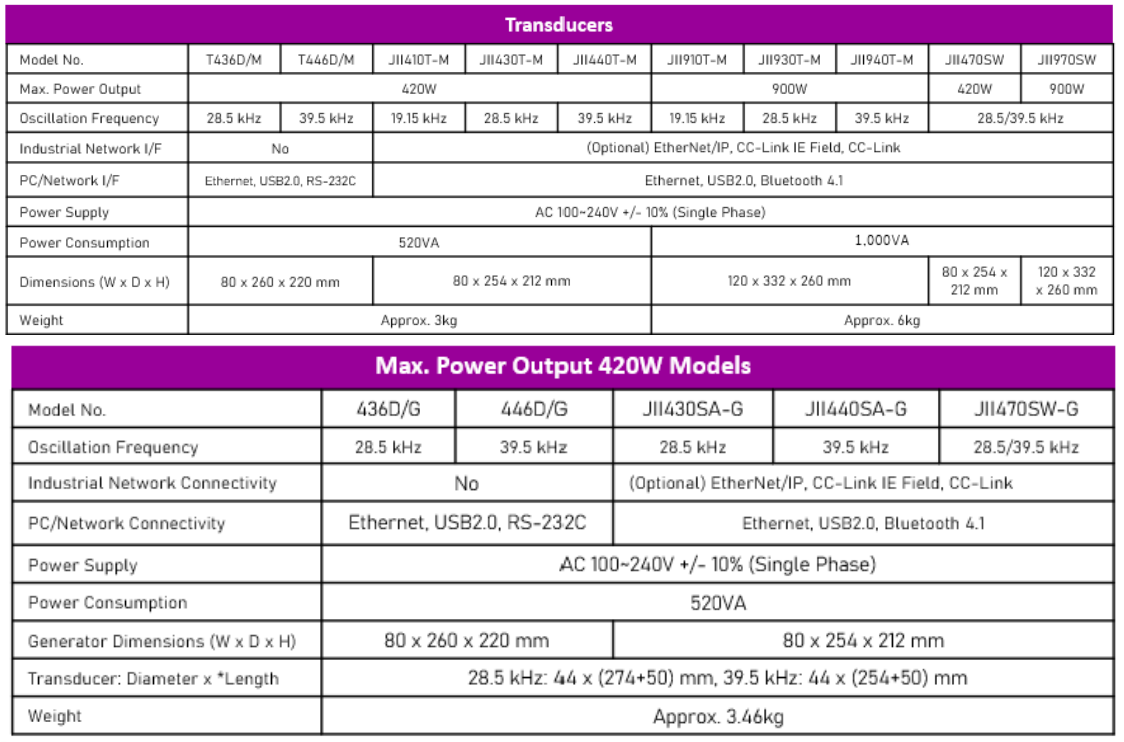

Compact Ultrasonic Welders

For applications where narrow transducers are needed, our line-up of low/mid-power ultrasonic welders have a proven track record of success. Available in two power outputs, multiple frequencies, and even two different interface configurations, our JII 4XX/9XX welders will get the job done right.

Press Mount Welders

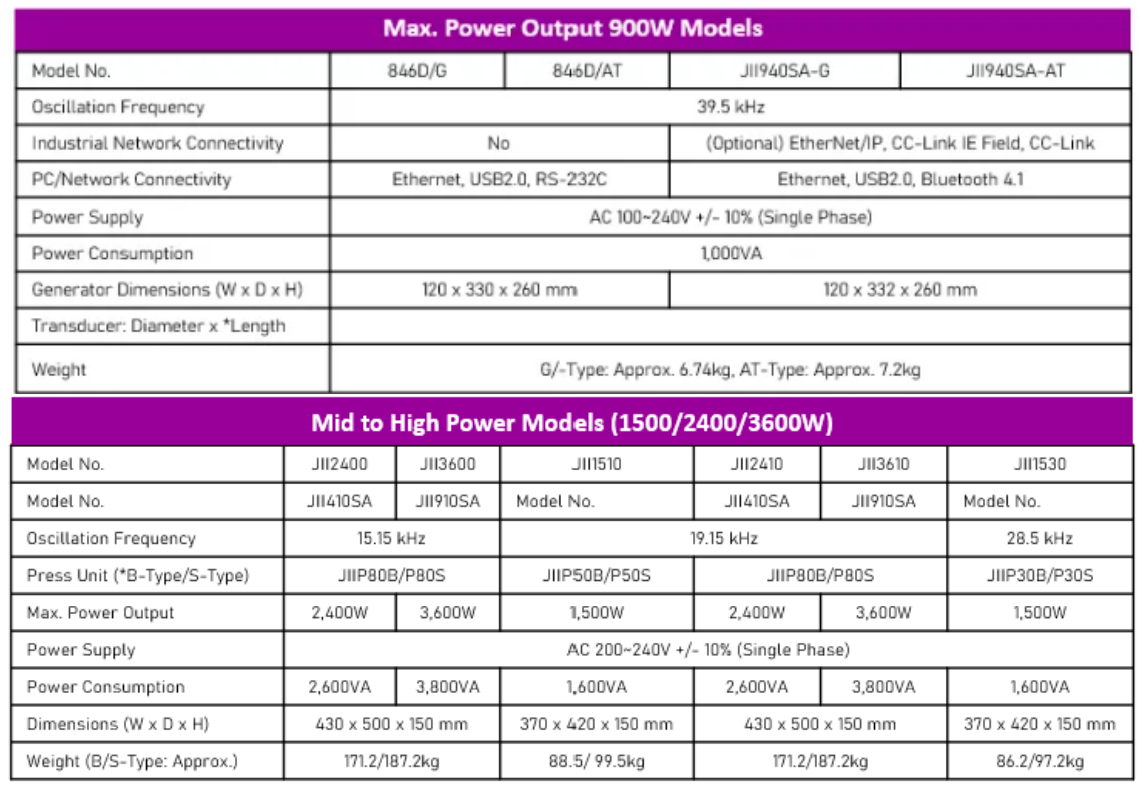

When the job calls for more power, a single horn to cover a larger workpiece footprint, or welding components further way from the point of contact, our high-power SONOPET SA-Type welders have you covered. Despite typically being used in full bench-press set-ups, these units are still fully capable of being incorporated into automated machines. Our standard press head can also be used as an all-in-one press assembly, combining our reliable pneumatics and our precision loadcell control system.

Multiple Types of I/O for PLC Communication

The JII Series can be equipped with several types of I/O to be used with industrial PLCs. We offer Discrete I/O, EtherNet IP, CC Link, and Industrial CC Link.

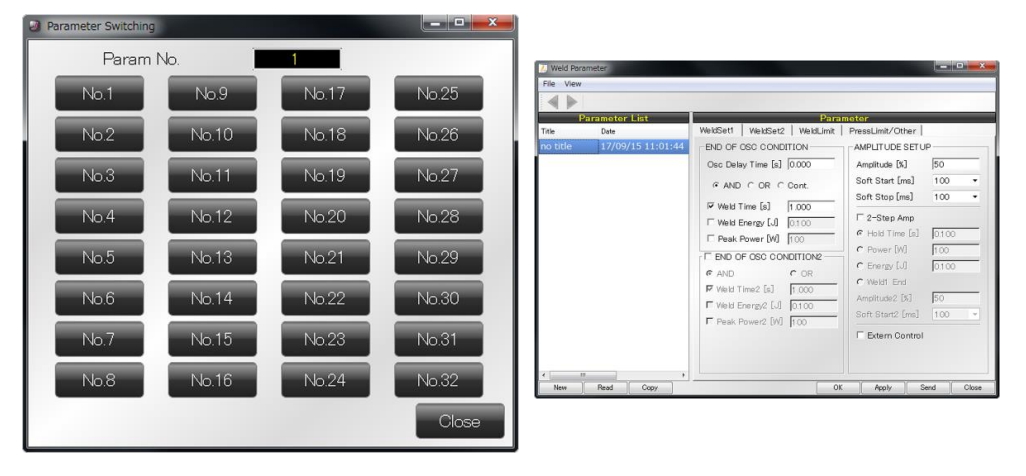

Multi-Parameter Settings

Every JII welder can store up to thirty-two (32) different parameter settings. This is ideal for use with systems connecting a single Generator to multiple Transducers, giving you the ability to weld with specific weld conditions for each point.

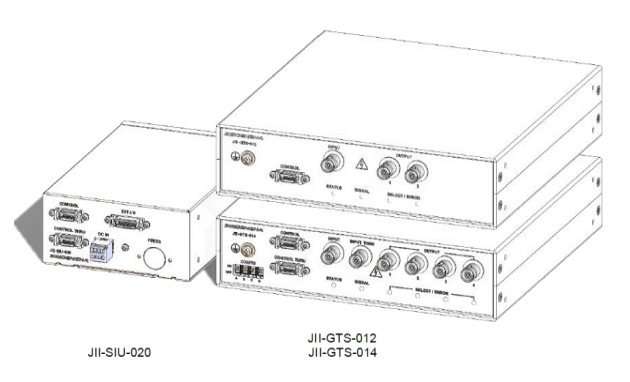

External Transducer Switch – JII-SIU

In order to reduce costs, fabricators often opt to have a single Ultrasonic Generator control multiple transducer units in sequence. While this adds to the overall cycle time, this is a cost-effective way of addressing applications where having a 1:1 of Generators to Transducers isn’t feasible due to space, design, or budget.

Seidensha offers an external switch box that can be daisy chained one after the other to allow a maximum of ten (10) Transducer units to be controlled from a single generator.

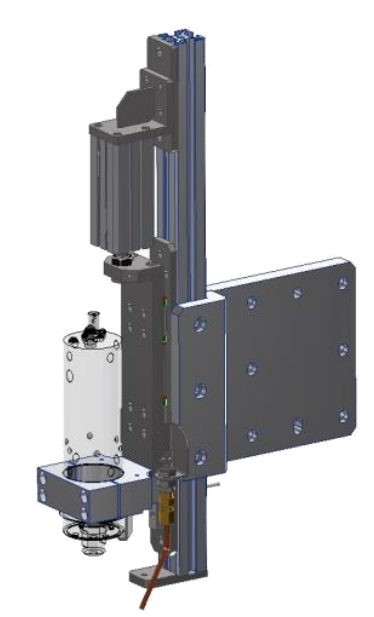

Off-the-Shelf Transducer Mountings

SEDECO and Seidensha have a variety of pre-designed transducer mountings for multi-head and/or robotic welding applications.

Our systems cover everything from the C-Clamp mounting bracket, LM Guide, Mechanical Hard-Stop, Air Cooling Tube, and a choice of pneumatic cylinder and position sensors, servo, or spring actuators.

Our systems can also incorporate smaller load cells to work with our additional hardware.