Our Products

Handheld & Compact Ultrasonic Welders

The right Interface for the right environment

Seidensha’s line-up of handheld and mid-power JII SONOPET Ultrasonic Welders come in two configurations:

• The 4X0/9X0, Zero-Series with NO external parameter adjusting interface

• The 4X1/9X1, One-Series that offers a more conventional LCD and front button control center

The Zero-Series is ideal for mass-production environments where team leaders want to “set it and forget it”. This unit is intended to reduce the amount of operator adjustment that can be made without a supervisor’s approval.

Settings can be made either via our JII Plus Bluetooth app, our Hand Controller Unit (HCU), or via PC with our Windows Based J-Tool software.

The One-Series offers a more direct adjustment method with an intuitive touch panel that offers immediate access to the weld output parameters and on-the-fly settings changes. Click the links above for more information on each series.

Versatile solutions for a range of applications.

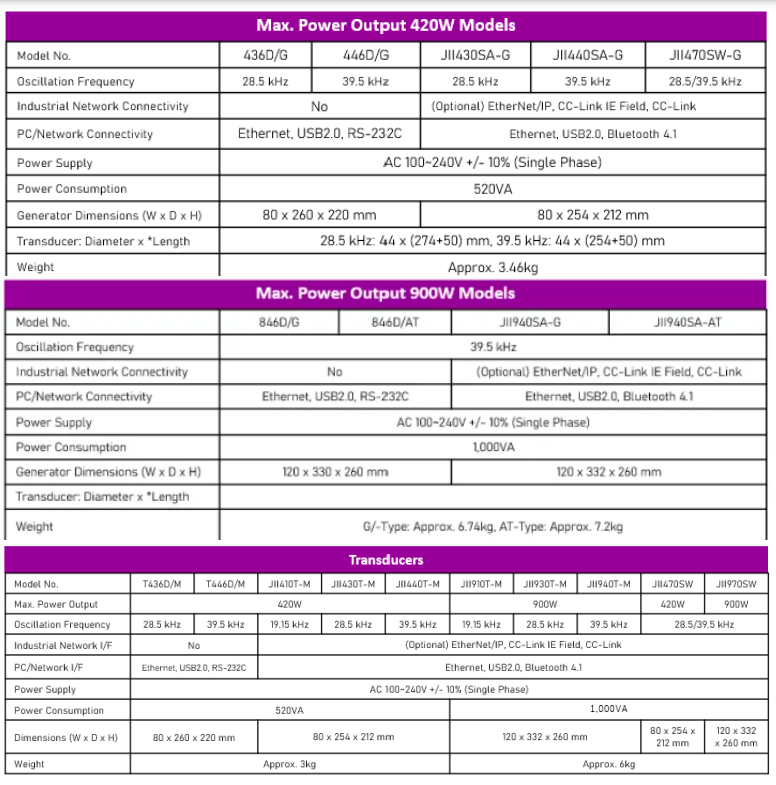

Seidensha’s line-up of compact welding equipment comes in two power outputs, both offering a range of different frequencies.

The 400 line offers a maximum output of 420W in 19.15kHz, 28.5kHz, or 39.5kHz.

This line-up is ideal for handheld applications or for automated cells that don’t require heaps of power.

SONOPET JII 4x1/9x1JII Series JII 400 Series JII 900 Series Versatile solutions for a range of applications.

The 900 line offers a maximum output of 900W in 19.15kHz, 28.5kHz, or 39.5kHz.

This line-up is indented for automated cells that require a moderate amount of power.

We recommend this line for 6-Axis Robotic Arm systems.

Used with our Welding Management Software

All of Seidensha’s JII welders can be used with our custom, Windows based software, J-Tool.

J-Tool allows for complete welder data management by recording the key parameter outputs and weld conditions for each weld point.

External Transducer Switch – JII-SIU

In order to reduce costs, fabricators often opt to

have a single Ultrasonic Generator control multiple transducer units in sequence. While this adds to

the overall cycle time, this is a cost-effective way of addressing applications where having a 1:1 of Generators to Transducers isn’t feasible due to space, design, or budget.

Seidensha offers an external switch box that can be daisy chained one after the other to allow a maximum of ten (10) Transducer units to be controlled from a single generator.